Welcome to NER - NEW ERA VIET NAM LIMITED COMPANY

Established in Vietnam, KY NGUYEN MOI NEWERA VIETNAM Co., Ltd - NEWERA, We want to become the leading manufacturer and supplier of scaffolding and formwork system. Relying on top quality and high credit standing, our brand "NER" scaffolding will win high praise from customers around the world in next time!

NEWERA – We consists of the main factory in Hoalac Hi-tech, Hanoi Vietnam and our longtime suppliers in North Vietnam which monthly output is more than 100 tons. With experienced technicians and advanced machinery, we are able to manufacture, various types of scaffolding and formwork systems as per customer's designs or samples.

Our main products include Scaffolding Sets, Scaffolding Frames (, Kwikstage, scaffolding Planks/ Walkboards, Multifunction/Baker Scaffolding, Scaffolding Tower Packages, Most Popular Tower Packages, Scaffolding Accessories, Scaffolding Safety, Accessories, Veneer Jack, Shoring, pecialty Items, marine products, adjustable shoring props, steel formworks, formwork clamps, steel pipes & couplers, adjustable U head jack & jack base, and other scaffolding accessories. ……..

About us

Located in the Hi-tech park area of Hanoi province, NER - NEW ERA VIET NAM LIMITED COMPANY is a professional manufacturer of scaffoldings, machine parts and formwork system. With many years experimence in metal processing, we are able to manufacture, various types of scaffolding and formwork systems as per customer's designs or samples. Our main products include Scaffolding Sets, Scaffolding Frames, Scaffolding Planks/Walkboards, Scaffolding Tower Packages, Most Popular Tower Packages, Scaffolding Accessories, Scaffolding Safety, Accessories, Veneer Jack, Multifunction/Baker Scaffolding, Shoring, Aluminum Scaffolding and other scaffolding accessories.

MANUFACTURING SYSTEM OF NEWERA

FEEDING MATTERIAL NEWERA

Use the best steel from a professional steel pipe manufacturer in Vietnam

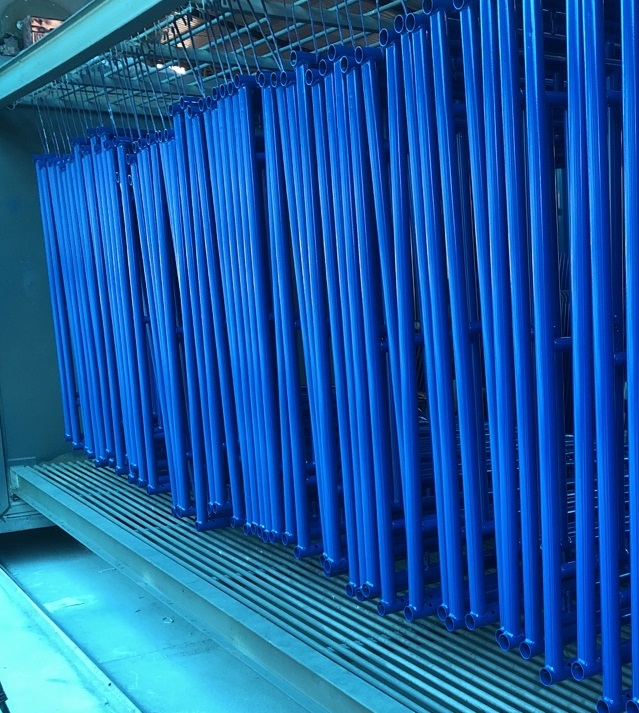

POWDER COASTING

Quality of powder coasting of NEWERA are very good. We have zinc phosphate procedure including many steps carefully

Robotic welding Scaffolding frame

Robotic welding for scaffoldings offers the following advantages to NEW ERA who need to change production tasks repeatedly:

Robotic welding allows NEW ERA to use an available labor pool for a minimal price

Automation can routinely place the same quality welds in the same spots, over and over again, with minimal human error, eliminating the repetitive boring jobs which could be a factor in welder turnover.

Less post-weld cleanup

Robotic welding can be very precise allowing for less weld spattering and neater seams.

Lower the cost of consumable materials

Filler material and weld wire are used more economically, and less wastefully, with robotic welding thereby reducing the overall cost of the scaffolds.

Reduction in total time to market

Scaffold parts move through the system more quickly with repeatable part placement and routines set for the robotic welder, allowing for potentially increased production

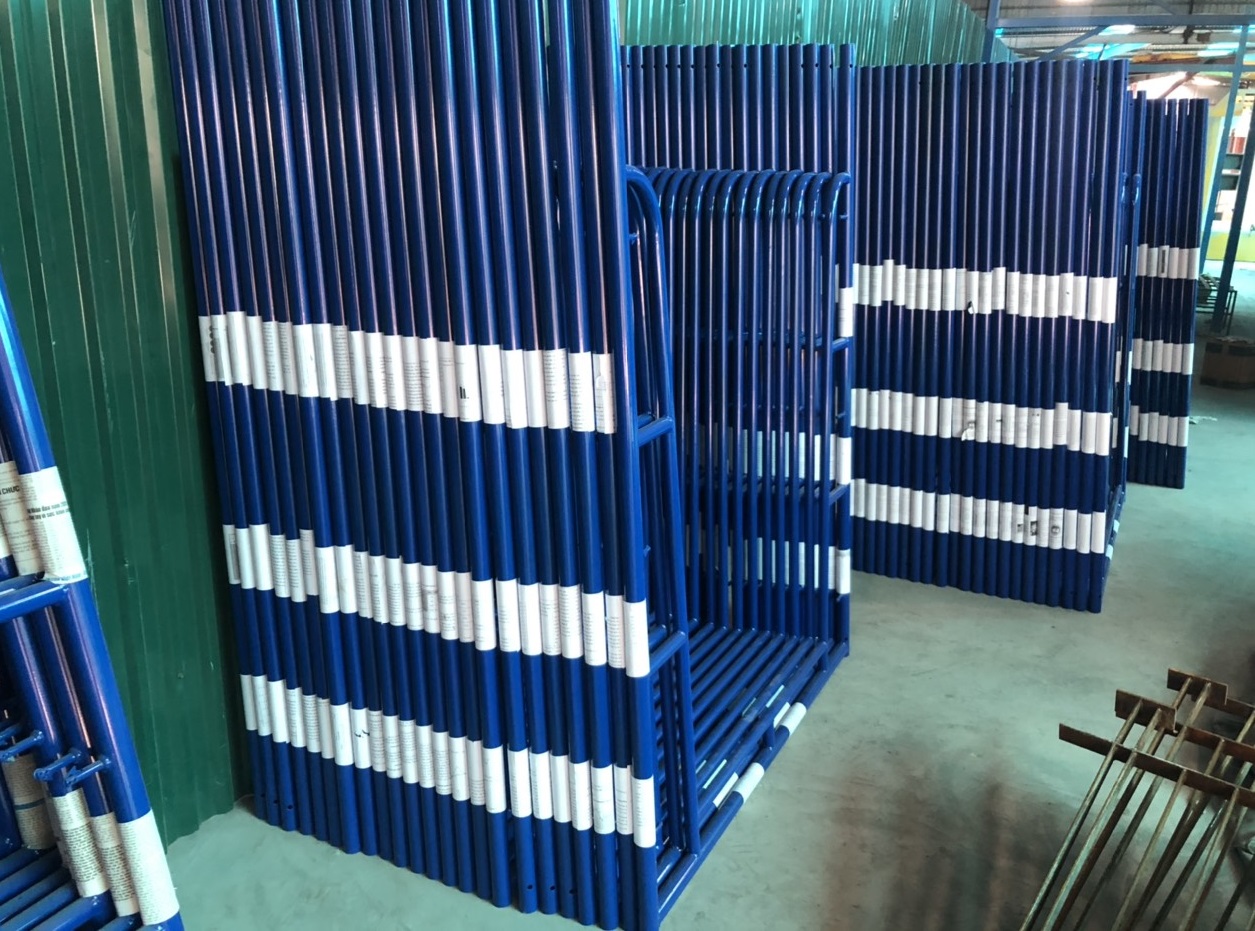

LOADING ON CONTAINER & ACCESORIES

After painting / powder coasting our products are carefully preserved in stock. An amount of inventory will be given to us for fast delivery

Securely fix products in containers to ensure products reach customers safely and easily when unloading

We consider several options to optimize shipping costs

Efficient arrangement to save shipping costs.

ACCESSORIES

NEW ERA and its partners have produced high quality accessories

Stay connected with us!

Join and cooperate with us to receive the earliest deals

Our team

We are proud to establish a reputable and quality company

Thành viên A

Thành viên A

Thành viên A